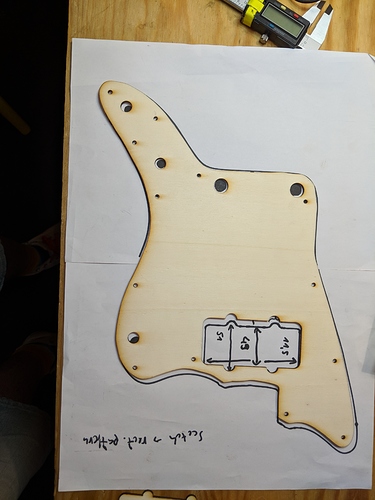

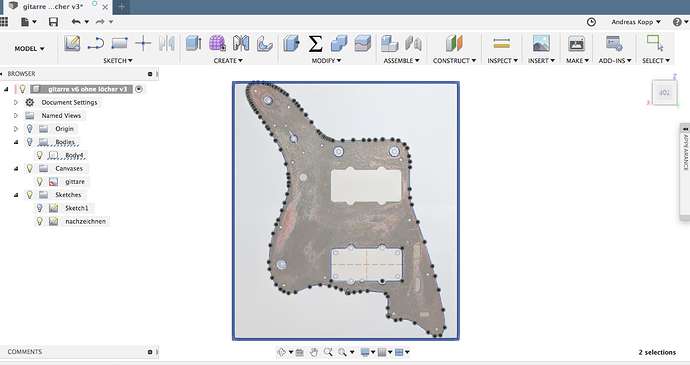

Flo came in today with a template of a pickguard of a fender jazzmaster guitarre and wanted to cut it in plexi glass. So I helped him to digitalize it tracing the template using Fusion360 and then I made a cad drawing in Fusion and exported as a pdf. In Inkscape I then removed the outside frame.

To trace it I made a picture scaled it and then with the spline tool we trace the outside. We decided not to cut the small ´holes but rather use the template to drill the wholes.

@Minirevollo made a suggestion to me that it would have been better to trace the template with a pencil and then use the scanner to avoid the distortion of a picture. Then I could have easily used the pdf in inkscape.

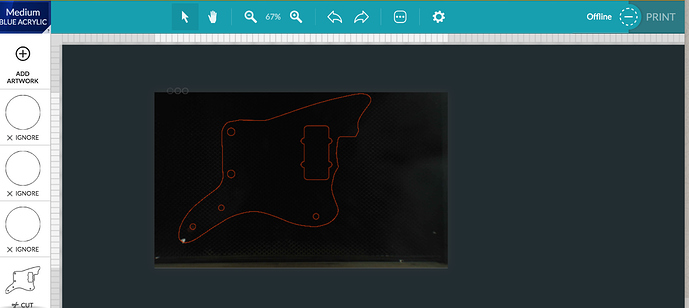

I just used the proofgrade settings for plexi. The thickness was 2.8 mm. There you have to be careful to put the piece a little bit more to the right as the proofgrade of glowforge is different to 2.8 mm

.FusionFile: gitarre v6 ohne löcher v3.f3d (2.0 MB)

Link: https://a360.co/2N1mz4V

pdf:gitarrev2.pdf (25.2 KB)