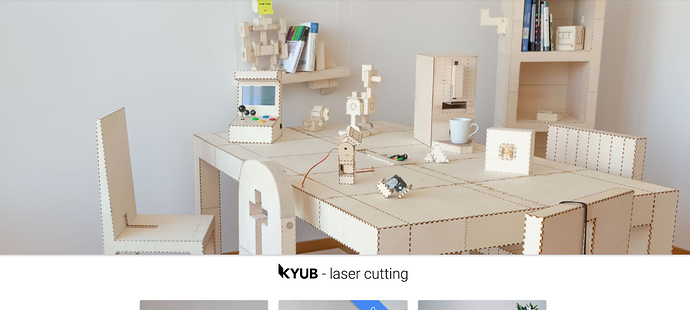

A couple of weeks ago at the Verbundstreffen in Lübbenau I met Patrick a professor from the Hasso Plattner Institut who had brought a whole furniture set, a guitare and a mini arcade with him all made with the software he and his team have developed.

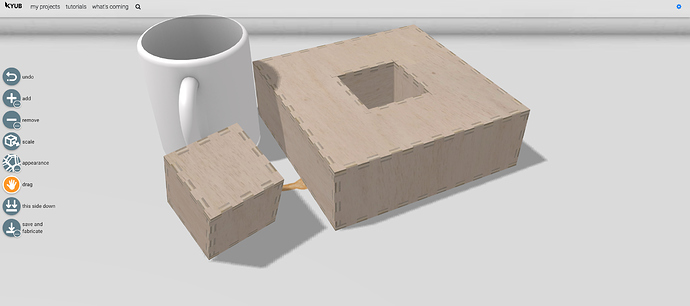

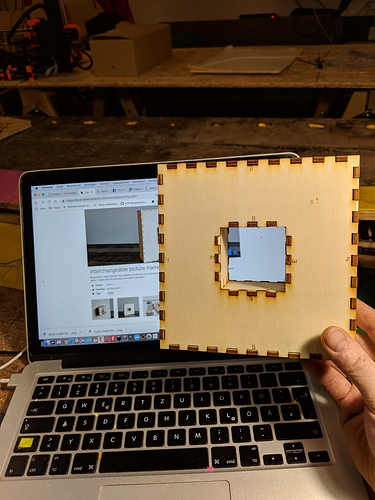

Yesterday I recevied the early access of the software called Kybub and I just got around playing around with it and first made the interchangeable picture frame. Thank you Patrick and team for working hard to release the software!

The software is online and you can finally create more complex lasercut designs than you could do with the famous makercase. More features like round corners, embeding cutting plans made with other software, internal plates for reinforcement and many more features are planned.

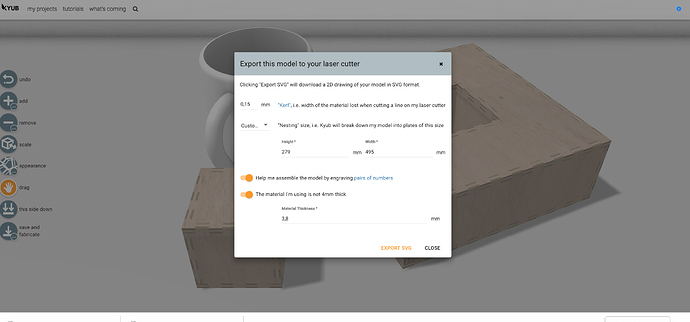

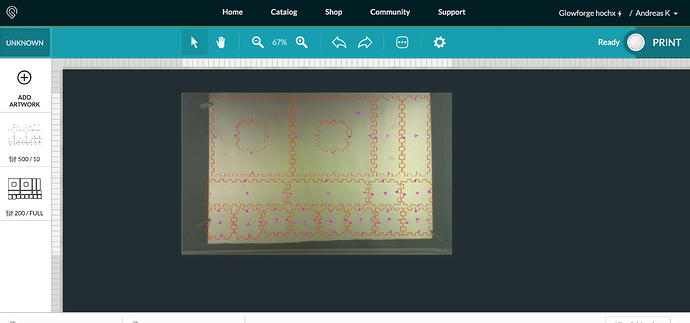

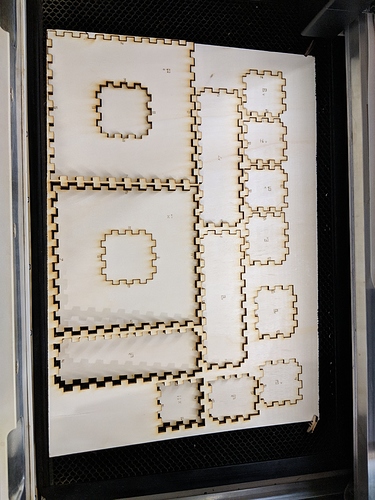

When finished with your design you can save it as a svg and can also decide for what size of lasercutter you have and what the kerf is. The size of our pine sheets are DIN A3 (297mmx420mm) and 4mm thick. But in reality they are between 3,6 and 3,8 mm. Our glowforge lasercutter has a American size cutting area of 11 by 19.5 inches or 279mm by 495 mm.

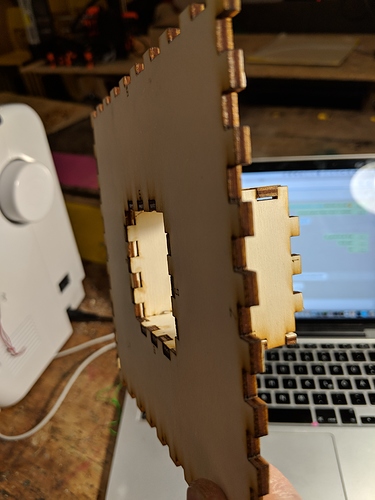

I could not get all the pieces on the board so I deleted one piece. Next time I should use 279 mm by 420mm instead of 279mm x 495mm. You can decide in the software to put pairs of numbers to help you put the pieces together. I scored these numbers. When putting together it took some time to understand them but then they where a great help. You only have to make sure that you always put the pieces facing outwards which I forgot. I also did not understand to put the inside picture frame together but I accomplished putting the frame and the hole together. I think I also have to readjust the curve a bit. The whole process was not easy but way easier then any other software. I tried to make the Erfindergarden logo this way in Fusion but have not yet completed. With this software I think I can easily to it in a couple of hours. Looking forward to the next features!